source:本站author:超級管理員time:2024-11-25views:7419

Do you know the characteristics of plasma coating machines? Let's learn and explore together:

Firstly, by controlling the ion energy and flow rate in the plasma, the plasma coating machine can improve the hardness, wear resistance, and corrosion resistance of the material, thereby increasing its service life and performance stability. Over time, this can improve the surface properties

2. The plasma coating machine can achieve nanoscale coating on the surface of materials, forming a uniform and dense coating with excellent optical, electrical, and thermal properties. It is a cleaning and spraying treatment for nanoscale coatings

In the field of optoelectronics, plasma coating machines can adjust the surface composition of materials by depositing mixed layers, thereby regulating the performance of semiconductor devices.

Compared with traditional coating technology, plasma coating machines can process material surfaces at lower temperatures, reducing energy consumption and heat loss. At the same time, this technology is environmentally friendly, does not require the use of harmful solvents and chemicals, and is highly efficient and environmentally friendly

The application range of plasma coating machine is very wide, covering multiple industries and fields such as electronics, optoelectronics, medical, automotive, etc.

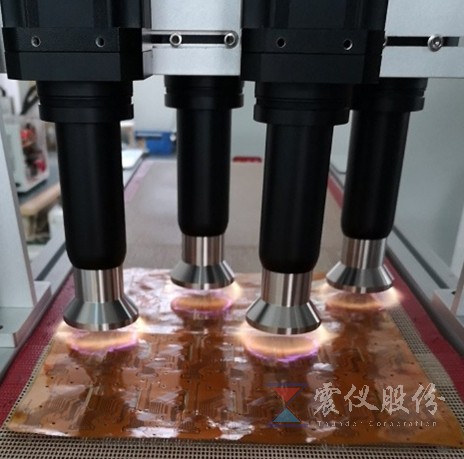

During plasma coating, the evaporated material particles move in the electric field along the direction of the wire in the form of charged ions, thus obtaining a good coating, which is much superior to ordinary vacuum coating that can only obtain coatings in the direct direction.

7. Good coating quality: The coating structure of plasma coating is dense, without pinholes, bubbles, uniform thickness, and even the edges and grooves can be uniformly coated.

8. The plasma coating process itself has the function of ion bombardment cleaning, which continues throughout the entire coating process. The cleaning effect is excellent, allowing the coating to directly approach the substrate and effectively enhance adhesion.

9. Plasma plating technology can deposit various materials, including metals, ceramics, polymers, etc., and is widely used in various process requirements.

The above characteristics have led to the widespread application and rapid development of plasma coating machines in modern industry. Apart from the popular features, what are their application ranges? Today, we will learn about the significant changes that occur when glass surfaces are treated with plasma coating machines!

1. Through plasma treatment, a large number of hydrophilic groups, such as hydroxyl groups, can be generated on the surface of glass, significantly improving its surface hydrophilicity. It makes it easier for the glass surface to bind with water molecules, forming a water film with better anti pollution and self-cleaning properties.

2. Plasma treatment can alter the surface energy of glass, giving it higher surface activity and adhesion. This change helps to improve the adhesion between glass and other materials, providing possibilities for the application of composite materials and coatings.

After plasma treatment, the hardness of the glass surface can be significantly improved, which helps to enhance the scratch resistance and wear resistance of the glass and extend its service life.

4. Enhance film adhesion: During the process of plasma bombardment on the surface of materials, gas molecules and pollutants adsorbed on the surface can be removed, which may also cause micro etching on the substrate surface, making the subsequent coated glass surface highly hydrophilic. This uneven and hydrophilic surface is conducive to the deposition of particles in optical glass coatings, improving the adhesion and uniformity of the coating.

5. Increase surface humidity: Glass substrates have strong hydrophilicity due to plasma cleaning, thereby increasing surface humidity.

6. Hydrophobic and oleophilic film layer: Select special monomers and plasma polymerize them into film layers with different polar groups, so that the surface of the product has hydrophobic and oleophilic functions. For example, when inputting different chemicals or liquids, glass needle tubes need to adjust their surface properties according to their characteristics to meet the needs of the application.

In summary, the application of plasma coating machines on glass surfaces can significantly improve the surface properties of glass, enhance its hydrophilicity, change surface energy, increase hardness, optimize optical performance, and thus expand the application of glass in many fields.

2025-03

Why plasma cleaning machines are so popular in the sem···

2025-06

Optical droplet angle refers to the angle between the ···

2021-09

We all know that the LED packaging process and the sem···

2024-12

What is the principle of using vacuum plasma cleaning ···

2021-09

Speaking of 3D arc trajectory deplating cleaning equip···