source:本站author:超級(jí)管理員time:2025-04-28views:15454454866

In recent years, with the increasing demand and constantly changing market environment, many manufacturers have undergone profound changes in environmental protection and process costs. Against this dual background, plasma cleaning technology stands out with its unique advantages and has become a popular choice in the field of thin film surface treatment.

What are the commonly used surface treatment methods for thin films on the market?

There are generally two common surface treatment methods for thin film materials: 1. plasma cleaning machine cleaning treatment, 2. corona machine cleaning treatment

Let's first talk about corona treatment machines, which are easy to operate and can also be produced continuously with assembly lines. But the disadvantage is that the discharge uniformity of the corona machine is poor, and the treatment effect is limited, which cannot fully meet the production requirements. At the same time, there are also problems such as easy film breakage, which have always been obstacles that corona treatment is difficult to control and overcome.

How does the plasma cleaning machine overcome the obstacles encountered by the corona machine?

Let's first understand that there are two common types of plasma cleaning machines, namely vacuum plasma cleaning machine and atmospheric pressure plasma cleaning machine. During vacuum operation, it is necessary to first place the film into the vacuum chamber, set specific parameters, and then process it; Normal pressure can be directly operated in atmospheric environment. The film is placed on the assembly line and moves at a constant speed with the conveyor belt.

Next, we will divide it into two parts: vacuum plasma cleaning machine and atmospheric pressure plasma cleaning machine. Under the action of plasma flame, the film is uniformly splashed onto the surface of the film to achieve the purpose of activating the film.

1. Vacuum plasma cleaning machine: In vacuum operation, the film needs to be placed in a vacuum chamber first, and then specific parameters need to be set before processing can be carried out. The seismograph vacuum plasma cleaning machine uses a high-frequency power supply and an ultra-high vacuum system to enhance surface adhesion through the synergistic effect of physical bombardment and chemical reduction of argon hydrogen mixed gas.

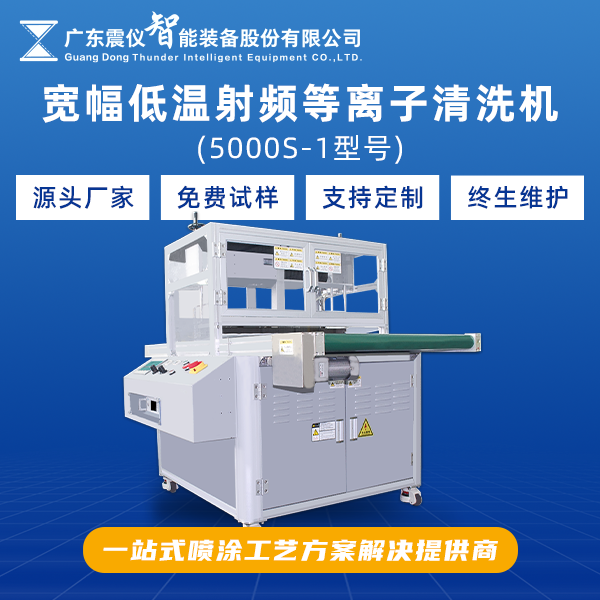

2. Atmospheric pressure plasma cleaning machine: No vacuum environment is required, and the plasma flame is directly sprayed uniformly on the surface of the thin film in the atmosphere. It can seamlessly connect to the production line and is suitable for high-speed production scenarios such as packaging film and industrial film. The atmospheric plasma cleaning machine of Zhenyi Co., Ltd. adopts a rotary spray head design and a dynamic temperature control system. The plasma is uniformly covered in atmospheric pressure environment, and after treatment, the target value is significantly increased, which can significantly improve welding and bonding performance.

In summary, whether using a normal pressure plasma cleaning machine or a vacuum plasma cleaning machine, the processing effect of thin film materials is as follows:

1. It can be integrated into automated production lines, with adjustable processing area and speed, improving production stability and efficiency;

2.Both types of plasma cleaning machines have the advantages of uniform and thorough cleaning, no pollution, efficient automation, and low temperature safety. They can quickly enhance the adhesion of films and meet the needs of film bonding, coating, or printing.

3. The plasma cleaning machine can also change the surface shape and chemical composition of thin film materials, thereby improving the stability, corrosion resistance, wear resistance, and insulation properties of the thin film.

Zhenyi Group conforms to the development needs of the times and continuously independently develops and upgrades atmospheric and vacuum plasma cleaning technology. It is also an innovation from concept to practice, committed to helping more enterprises solve problems such as residual stains and insufficient adhesion on material surfaces.

If you need to learn more about plasma cleaning machine solutions, please contact Zhenyi Group's friends!

2021-12

AF anti-fingerprint coating spraying machine how to ch···

2025-04

Before packaging printing, plasma cleaning machines ca···

2025-03

In the traditional sense, what are the differences bet···

2021-09

As one of the technology architectures for face recogn···

2021-12

When you just began to operate a plasma cleaning machi···