source:本站author:超級(jí)管理員time:2024-12-31views:5748977

Why has the plasma cleaning machine been welcomed by a large number of industrial enterprises since its inception? It has undergone physical and chemical modifications to the surface, which can improve the adhesion of the surface to a certain extent.

The role of plasma cleaning equipment can be said to be quite significant. The following are the applications of atmospheric pressure plasma cleaning equipment in the semiconductor field.

Firstly, the activation cleaning process of plasma cleaning machines is a key technology for reducing costs and improving reliability. Plasma cleaning machine can activate the cleaning of residues on the surface of chip printed circuit boards. In the production process of semiconductor materials, almost every step needs to be cleaned, and the quality of circular cleaning has a great impact on the performance of the equipment.

Due to the fact that circular cleaning is a key repetitive process in semiconductor manufacturing, the quality of its workplace will directly affect the output, performance, and reliability of the equipment. Plasma cleaning machine, as a modern dry cleaning technology, has the characteristics of low-carbon and environmental protection.

Nowadays, with the rapid development of the electronic optics industry, seismograph plasma cleaning machines are increasingly being used in the semiconductor industry. Nowadays, with the rapid development of semiconductor technology, the process standards are getting higher and higher, especially the surface quality of semiconductor material wafers. The main reason for the damage of particles and metal debris on the surface of the wafer is the serious impact on equipment quality and yield.

During the production, transportation, and storage of wafers, their surfaces may adsorb various organic substances such as photoresist, grease, dust, etc. The plasma cleaning machine decomposes the active particles in the plasma into volatile substances through chemical reactions with organic matter, thereby achieving the purpose of removal. For example, after the photolithography process, plasma cleaning machines can effectively remove residual photoresist, providing a clean surface for subsequent processes.

Plasma cleaning equipment has simple process, easy operation, no waste disposal, air pollution and other problems. However, it cannot remove carbon and other non-volatile metals or metal oxides. Plasma cleaning machines are typically used to remove photoresist by introducing a small amount of oxygen into the plasma reaction system. Oxygen generates plasma under the action of a strong electric field and rapidly oxidizes the photoresist into volatile gas state substances.

The plasma cleaning machine has the advantages of easy operation, high efficiency, surface cleaning, and scratch free, which is conducive to ensuring product quality. It does not require acid, alkali, or organic solvents as cleaning materials, nor does it pollute the environment.

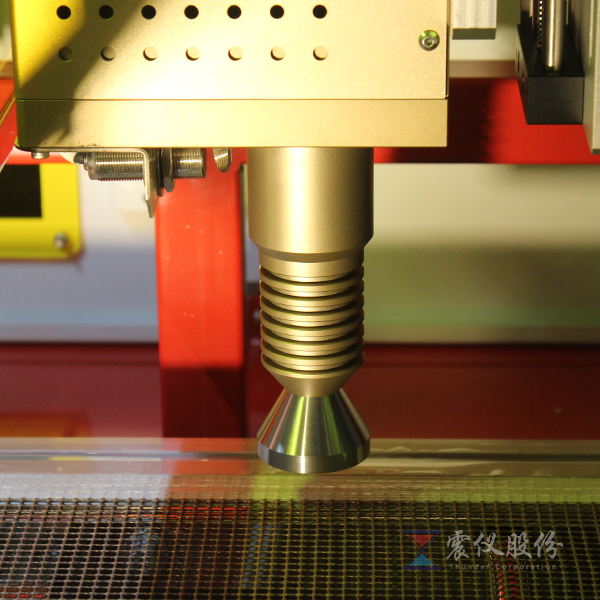

The seismograph plasma cleaning machine is an irreplaceable mature process, whether it is chip source ion injection, crystal element coating or our low-temperature plasma surface treatment equipment: removing ultra purification treatment and surface activation, such as oxide film, organic matter and support film, to improve the permeability of crystal element surface.

The application scope of plasma cleaning machine mainly includes cleaning experimental tools in university laboratories, bonding of shoe soles and uppers, cleaning of automotive glass coating films, and plasma treatment to make the bonding more firm, such as lamps, glass, textiles, plastic printing, optoelectronic materials or metals. In addition, the vacuum plasma cleaning machine can also remove inorganic substances such as metal ions and oxides on the wafer surface. With the help of plasma bombardment, inorganic substances can react with particles in the plasma or be directly sputtered off, such as removing the naturally formed oxide layer on the wafer surface, ensuring the purity of the wafer surface.

Plasma cleaning technology can also improve the bonding effect. During the wafer bonding process, the plasma cleaning machine can remove pollutants and oxide layers on the wafer surface, improve surface cleanliness and activity, change the surface microstructure, make it rougher, increase surface energy, and improve the wettability and adhesion of the wafer surface. These changes help to enhance the bonding strength between wafers, reduce potential voids and defects during the bonding process, and further improve bonding quality.

2021-09

Plasma cleaners have now occupied half of the product ···

2025-03

The plasma cleaning machine modifies the surface of si···

2025-05

I believe everyone is familiar with plasma treatment, ···

2021-09

I believe that friends who have read my previous conte···

2025-05

How to use anti glare AG equipment to protect against ···