source:本站author:超級管理員time:2024-12-06views:9137

Plasma cleaning machine, a secret weapon that can quickly improve the spraying effect on the surface of composite materials!

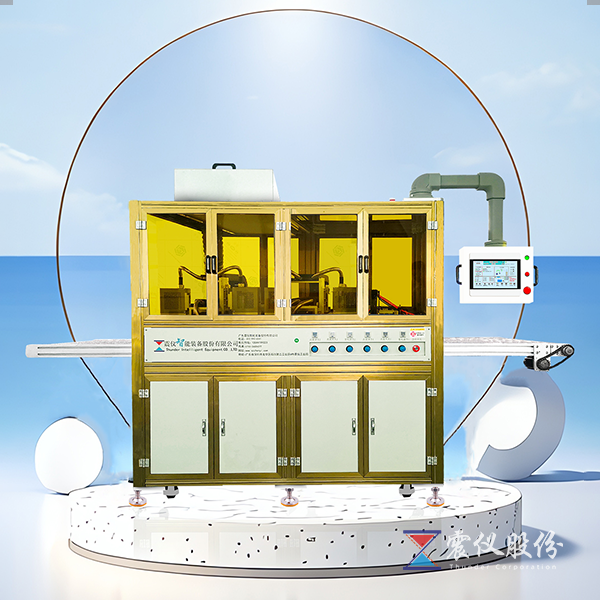

With the continuous advancement of science and technology, our understanding of various new materials and their surface treatment technologies is also deepening. Among them, plasma cleaning machine, as an efficient cleaning equipment, is gradually playing an important role in the field of surface spraying of composite materials such as glass fiber/carbon fiber/epoxy resin/silicone rubber. Today, following the editor, we will delve into how plasma cleaning machines can improve the surface spraying effect of composite materials.

Firstly, we need to understand what a plasma cleaning machine is and how it works. A plasma cleaning machine is a device that uses electron acceleration and collision reactions to generate gas molecules and form plasma. Low temperature plasma is a high-energy density state of matter that can effectively remove organic residues on the surface of workpieces.

The plasma cleaning machine performs fine selective cleaning, and when the daughter shoots towards the surface of the material, it only attacks the contaminated part without affecting the integrity of the material. This can avoid a decrease in coating quality caused by excessive cleaning.

The deep cleaning ability of plasma cleaning machine is also its outstanding feature. Plasma can enter the interior of materials and undergo chemical reactions with organic pollutants, thus enabling thorough cleaning at the microscopic level of materials. This can achieve higher adhesion and more uniform distribution of the surface sprayed coating, thereby improving the overall coating effect. Through its fine selectivity and deep cleaning ability, the plasma cleaning machine effectively improves the surface spraying effect of composite materials.

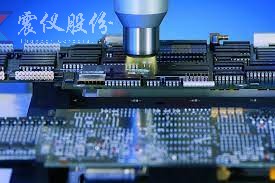

Low temperature plasma is a special gas discharge phenomenon, which is a low-temperature state with high energy density and strong chemical reactivity. Therefore, it has broad application prospects in the field of material surface treatment, compared with traditional high-temperature plasma. In recent years, plasma cleaning technology has been successfully applied in semiconductor devices, coatings, biomedical and other fields, providing important technical support for research and development in these areas. Do you know the advantages of plasma technology in the application of new energy fields such as wafers?

1. Improve photoelectric conversion efficiency: According to the treatment of the plasma cleaning machine, defects and dirt on the surface of polycrystalline silicon cells can be removed, and the absorption rate of light energy can be increased, thereby improving the photoelectric conversion efficiency.

2. Reduce reflectivity: Plasma cleaning technology can form a uniform and dense oxide layer on the surface of polycrystalline silicon cells, effectively reducing the reflectivity of light and improving the efficiency of photovoltaic power generation,

3. Extend battery life: Plasma cleaning treatment can reduce microcracks and defects on the surface of polycrystalline silicon batteries, slow down the battery's decay rate, and extend the battery's service life.

4. Reduce production costs: Plasma cleaning machine is an environmentally friendly and efficient surface treatment method that can replace traditional mechanical grinding and chemical corrosion, reducing production costs.

In summary, based on the inherent characteristics of plasma cleaning machines and their application advantages in fields such as batteries, they can remove defects and dirt on the surface of polycrystalline silicon cells during the processing, forming a uniform and dense oxide layer. Low temperature plasma treatment technology provides an effective method for solving surface problems in polycrystalline silicon cells. With the continuous advancement and improvement of this technology, I believe it will have broader application prospects in the future field of solar energy.

2025-02

AF anti fingerprint coating can reduce fingerprints an···

2021-09

We all know that many surface displays of these displa···

2025-05

AG anti glare equipment: Say goodbye to glare troubles···

2021-10

Plasma cleaners can be divided into many types, such a···

2025-06

What is plasma etching machine cleaning technology and···